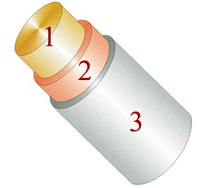

Optical fibre consists of:

- core (1) on which, mainly, a optical signal spreads;

- cladding (2)), impedimental the exit of light from a fibre to arrival on the end of cable (thus core refractive index more than refractive index of environment);

- buffer (3), fibre intended for defence from external influences of environment.

|

|

Core

First a distinction is made between silica with high or low OH content. Silica fibers with high OH (600-1000 PPM) are used in the UV/VIS wavelength range because of the low absorption in the UV. For Deep-UV applications (below 230 nm) special solarization resistant fibers can be used.

The water content causes strong absorption peaks in the NIR wavelength range. In order to get appropriate fibers for the NIR range, the "water" is removed from the silica. This results in low OH fibers (<2 PPM) with low absorption in the NIR.

Cladding

In order to get the light guiding effect the core is cladded with a lower index of refraction material. For the highest quality fibers with the lowest absorption this is a fluorine-doped silica, the so-called silica-silica or all-silica fibers with a numerical aperture (NA) of 0.22.

Buffer

Without further protection fibers would easily break, because of small scratches or other irregularities on the surface. Therefore a next layer, the buffer, is added. This buffer also determines under what circumstances the fiber can be used. Temperature range, radiation, vacuum, chemical environment and bending are factors to be considered.

|